Talk to us

07971671193( PIN:967)

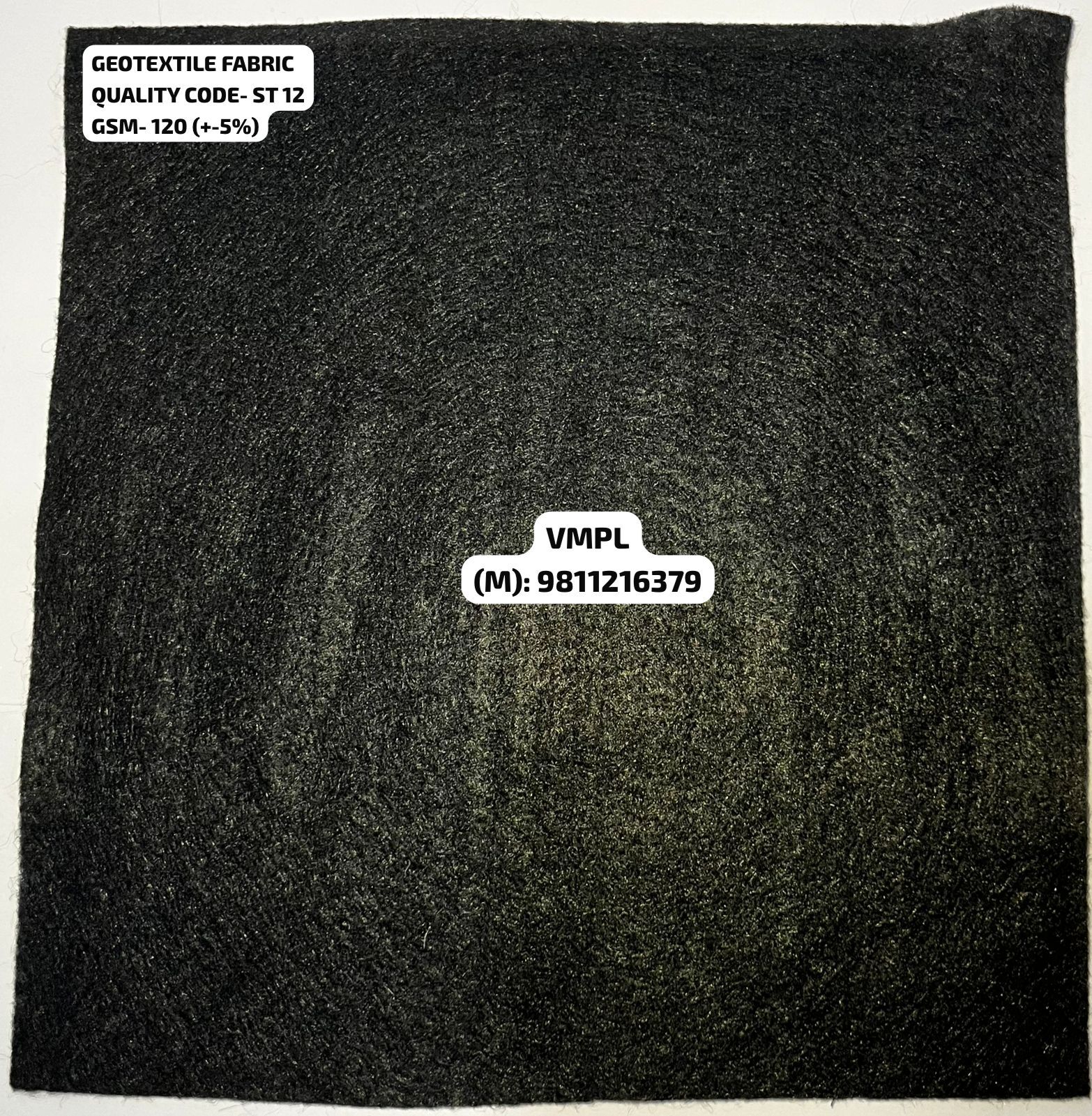

Nonwoven geotextile fabrics are versatile and can be tailored to specific needs depending on their construction and application.

Price:

Price 100.00 INR / Roll

Minimum Order Quantity : 1 Square Meter

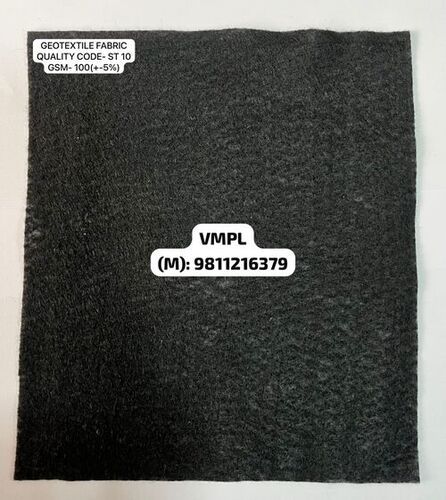

Pattern : Non Woven Needle punch

Width : 1.47mtr Meter (m)

Length : 50 Meter (m)

Texture : Plain

Price 1.00 INR / Meter

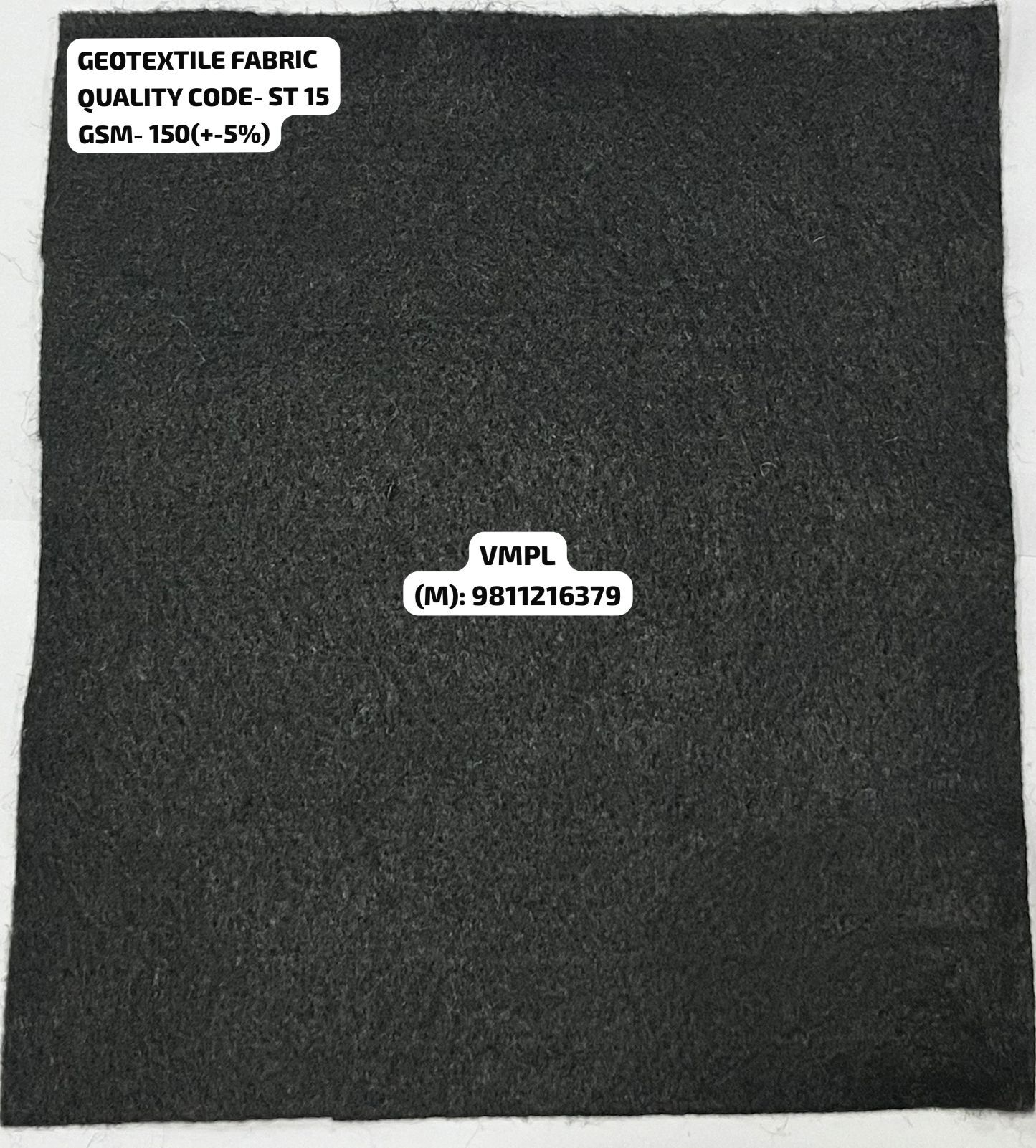

Minimum Order Quantity : 10 Rolls

Pattern : Plain

Width : 2.1MTR Meter (m)

Length : 200 Meter (m)

Texture : Non Woven

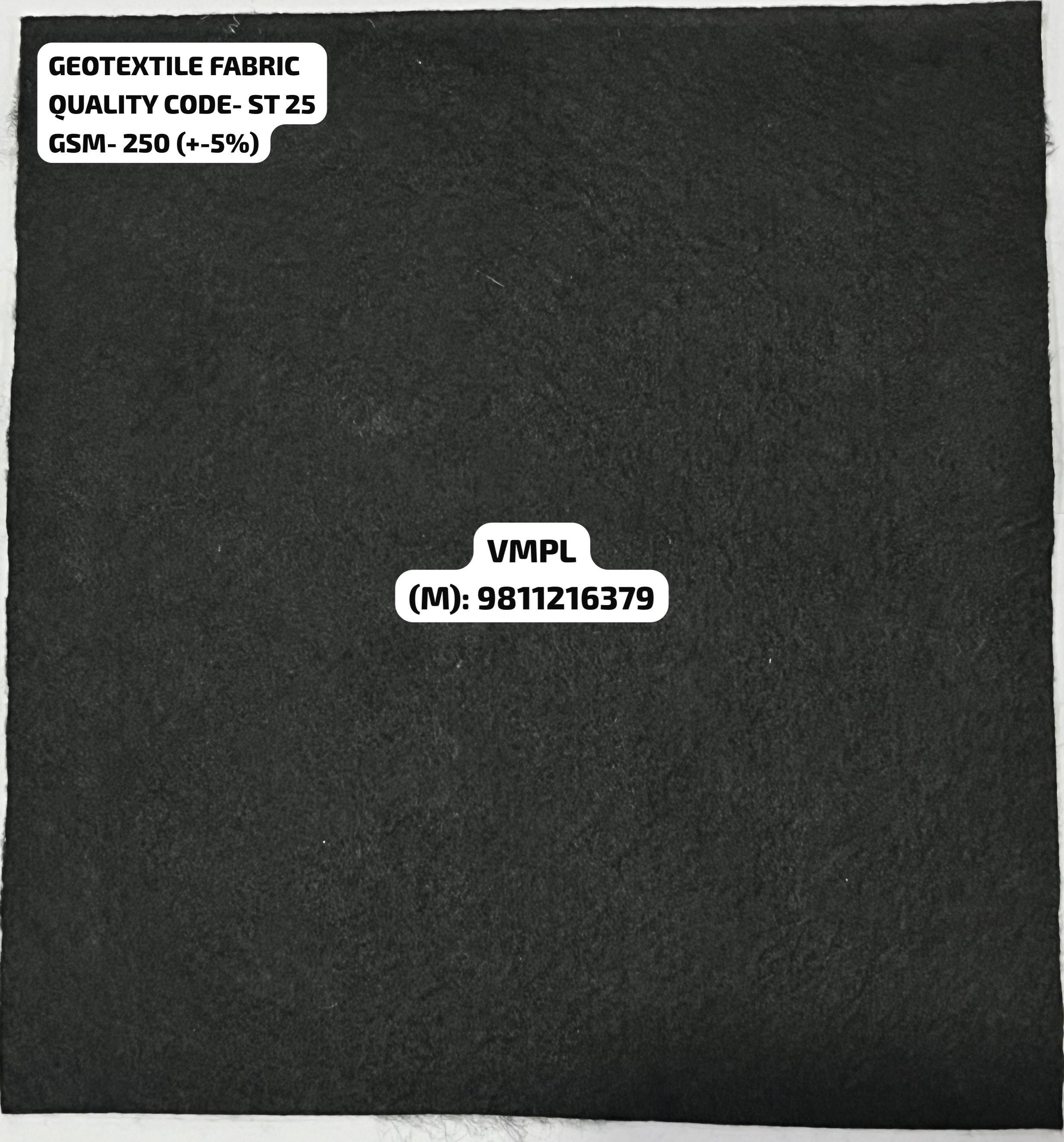

Minimum Order Quantity : 10 Rolls

Pattern : Plain

Width : 2.1MTR Meter (m)

Length : 200 Meter (m)

Texture : Non Woven